Flow Induced Crystallization Theories¶

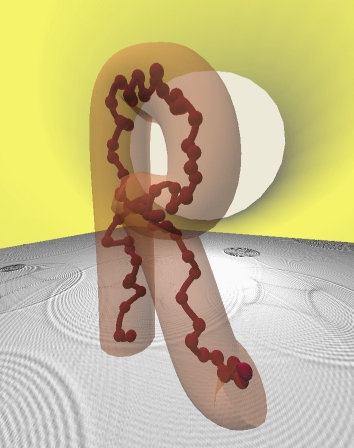

GO-polySTRAND model for flow-induced nucleation¶

Summary¶

Description¶

For full details about how the predictions are calculated, refer to [1].

Smooth-polySTRAND model for flow-induced nucleation¶

Summary¶

Smooth-polyStrand model for flow-induced crystallisation in polydisperse melts of entangled linear polymers

Rheological model: The Rolie-Double-Poly model

- Evolution of chain structure under flow is computed by the Rolie-Double-Poly model. Implementation and parameters are the same as in the NVLE application.

- \[\boldsymbol \sigma = G_N^0 \sum_i g(Z_{\text{eff},i}) \text{fene}(\lambda_i) \phi_i \boldsymbol A_i\]

- where

- \[\begin{split}\boldsymbol A_i &= \sum_j \phi_j \boldsymbol A_{ij}\\ \lambda_i &= \left( \dfrac{\text{Tr} \boldsymbol A_i}{3} \right)^{1/2}\\ \stackrel{\nabla}{\boldsymbol A_{ij}} &= -\dfrac{1}{\tau_{\mathrm d,i}} (\boldsymbol A_{ij} - \boldsymbol I) -\dfrac{2}{\tau_{\mathrm s,i}} \dfrac{\lambda_i - 1}{\lambda_i} \boldsymbol A_{ij} -\left( \dfrac{\beta_\text{th}}{\tau_{\mathrm d,j}} + \beta_\text{CCR}\dfrac{2}{\tau_{\mathrm s,j}} \dfrac{\lambda_j - 1}{\lambda_j}\lambda_i^{2\delta} \right) (\boldsymbol A_{ij} - \boldsymbol I)\\ \text{fene}(\lambda) &= \dfrac{1-1/\lambda_\text{max}^2}{1-\lambda^2/\lambda_\text{max}^2}\end{split}\]

with \(\beta_\text{th}\) the thermal constrain release parameter, set to 1. If the “modulus correction” button is pressed, \(g(z) = 1- \dfrac{c_1}{z^{1/2}} + \dfrac{c_2}{z} + \dfrac{c_3}{z^{3/2}}\) is the Likhtman-McLeish CLF correction function to the modulus (\(c_1=1.69\), \(c_2=2\), \(c_3=-1.24\)), \(g(z) = 1\) otherwise; \(Z_{\text{eff},i}=Z_i\phi_{\text{dil},i}\) is the effective entanglement number of the molecular weight component \(i\), and \(\phi_{\text{dil},i}\) the dilution factor (\(\phi_{\text{dil},i}\leq \phi_i\)).

Nucleation model: The smooth-polyStrand model

This model takes the stress output from the Rolie-Double-Poly model for each mode, computes the flow-induced nucleation rate, using the Kuhn segment nematic order as the order parameter.

-Neglect quiescent nucleation button: this subtracts the quiescent nucleation rate and assumes all quiescent nucleation occurs from hetrogeneous nuclei.

-Average to single species button: this preaverages the chain configuration over all species in the melt and computes the nucleation rate with a single species based on this average.

Crystal evolution model: The Schneider rate equations

From the computed nucleation rate and the crystal growth rate, the model computes the evolution of total crystallinity using the Schneider rate equations [W. Schneider, A. Koppl, and J. Berger, Int. Polym. Proc.II 3, 151 (1988)]. This calculatiom uses the Avrami expression to account approximately for impingement.

- Parameters

Rheological

GN0\(\equiv G_N^0\): Plateau modulusbeta\(\equiv\beta_\text{CCR}\): Rolie-Poly CCR parameterdelta\(\equiv\delta\): Rolie-Poly CCR exponentphi_i\(\equiv\phi_i\): Volume fraction of species \(i\)tauD_i\(\equiv\tau_{\mathrm d,i}\): Reptation time of species \(i\) (including CLF)tauR_i\(\equiv\tau_{\mathrm s,i}\): Stretch relaxation time of species \(i\)lmax\(\equiv\lambda_\text{max}\): Maximum stretch ratio (active only when the “fene button” is pressed)Ne\(\equiv N_e\): Number of Kuhn steps between entanglements

Quiescient Crystallisation

epsilonB\(\equiv \epsilon_B\): Bulk free energy gain of crystallisation per Kuhn step [dimensionless]muS\(\equiv \mu_S\): Nucleus surface area cost [dimensionless]tau0\(\equiv \tau_0\): Kuhn step nucleation timescale [sec]rhoK\(\equiv \rho_K\): Kuhn step density [\(\mu\mathrm{m}^{-3}\)]G_C\(\equiv G_C\): Crystal growth rate [\(\mu\mathrm{m/sec}\)]N_0\(\equiv N_0\): Heterogeneous nucleation density [\(\mu\mathrm{m}^{-3}\)]

Flow-induced crystallisation

Gamma\(\equiv \Gamma\): Prefactor connecting the Kuhn segment nematic order and the monomer entropy loss [dimensionless].Kappa0\(\equiv \kappa _0\): Free energy penalty for the nucleus surface roughness [dimensionless].Qs0\(\equiv Q_{s0}\): Parameter setting the volume of the search region for new stems joining the nucleus [dimensionless].

Description¶

For full details about how the predictions are calculated, refer to [1].

References

Daniel J. Read, Claire McIlroy, Chinmay Das, Oliver G. Harlen, and Richard S. Graham. PolySTRAND model of flow-induced nucleation in polymers. Physical Review Letters, apr 2020. URL: https://doi.org/10.1103%2Fphysrevlett.124.147802, doi:10.1103/physrevlett.124.147802.